Air Operated Double Diaphragm Pumps - AODD Pumps

PATENTED WORLDWIDE

BOXER Technology AODD Pumps

PATENTED WORLDWIDE Pneumatic Exchanger Technology

COMPACT AND MODERN DESIGN

FOR ALL INDUSTRIAL APPLICATIONS

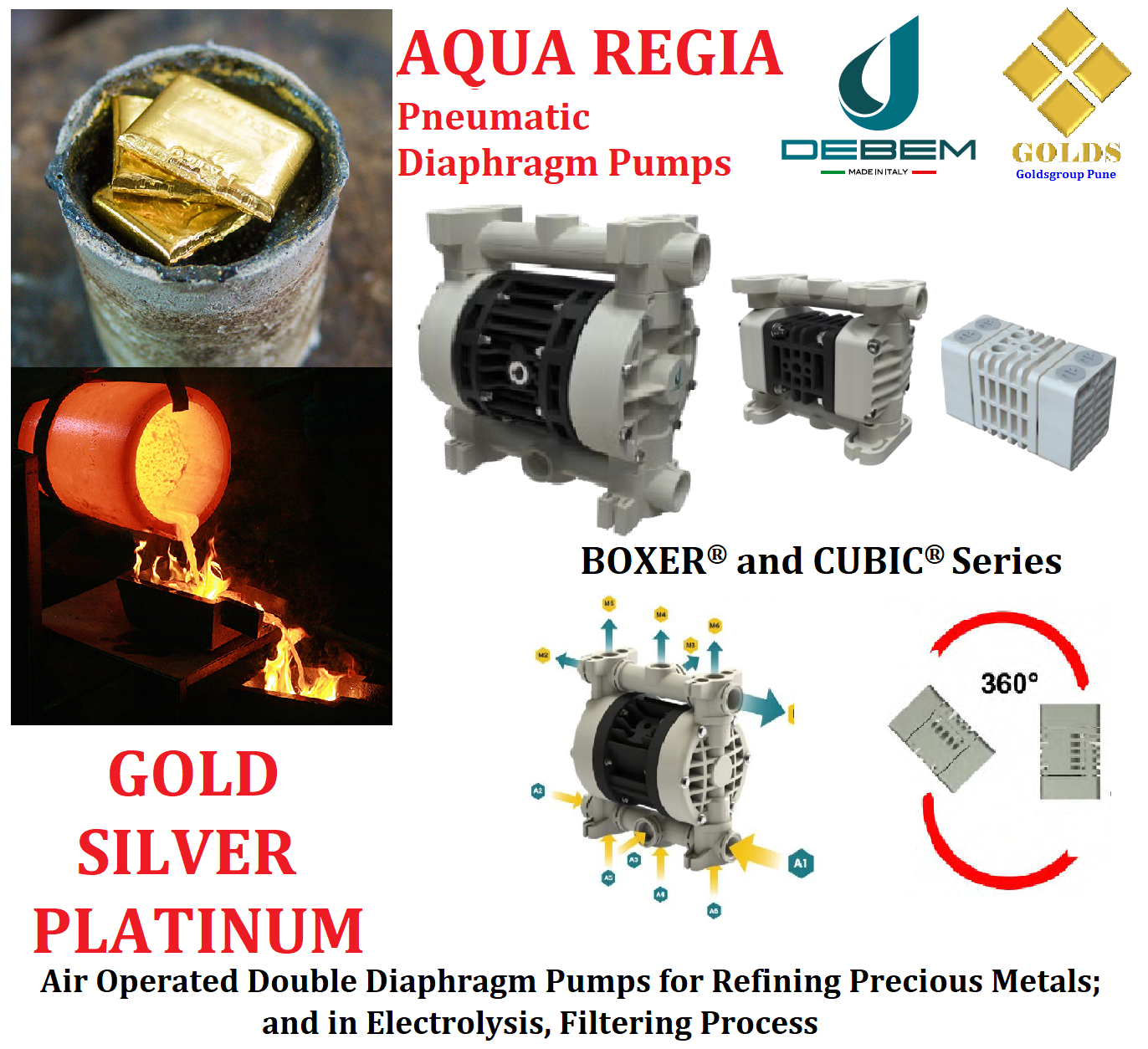

DEBEM PUMPS FOR AQUA REGIA

Transfer and Circulation of Hydrochloric Acid HCL Nitric Acid mixture for Golds Refining Plant Golds Processing Plant Precious Metal Processing Plant and Scrubbing application has Highest Market Share Globally and in India

TRULY INNOVATIVE - LONGEST OPERATIONAL SERVICE LIFE ACHIEVED - VERY LESS MAINTENANCE - PART REPLACEMENTS NEEDED.

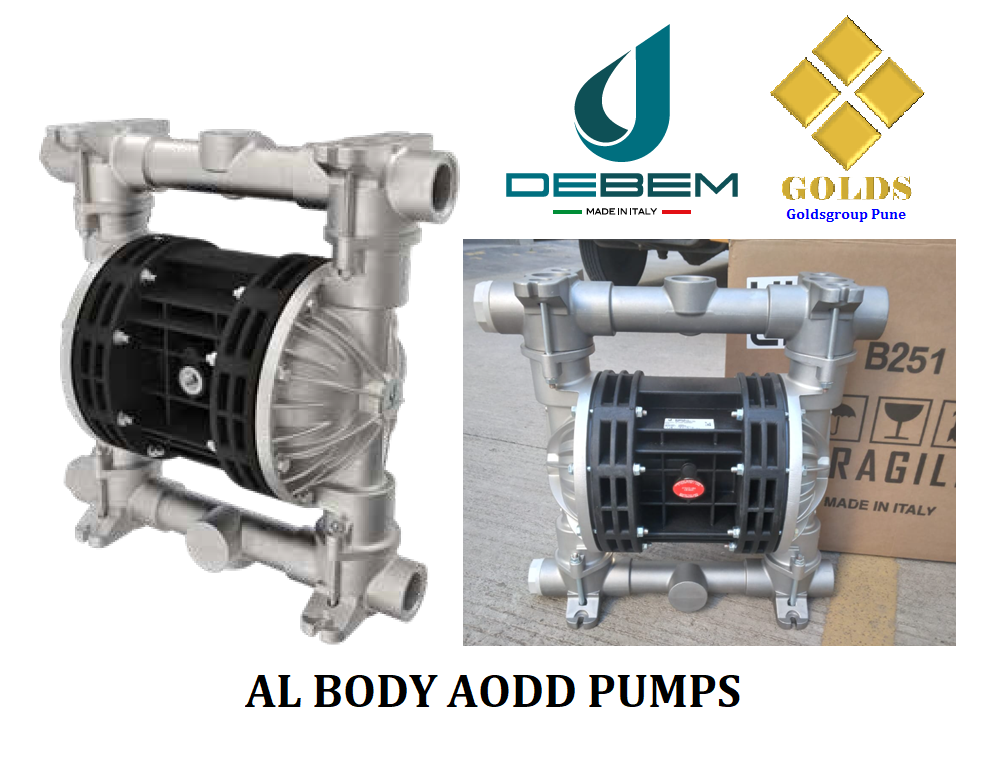

BOXER ALUMINUM AL BODY PUMP SERIES

CHOSEN BY WORLD LEADERS LIKE BOBST - TRESU - ITALWISAD - NEW LAC - INX - BFM - INVEBI - LTF - PPG - RESERVE BANK OF INDIA (RBI) CURRENCY MINT - BEKAERT - and many others

PNEUMATIC INK PUMPS - PNEUMATIC SOLVENT CIRCULATION PUMPS - AT EVERY STAGE OF OPERATION

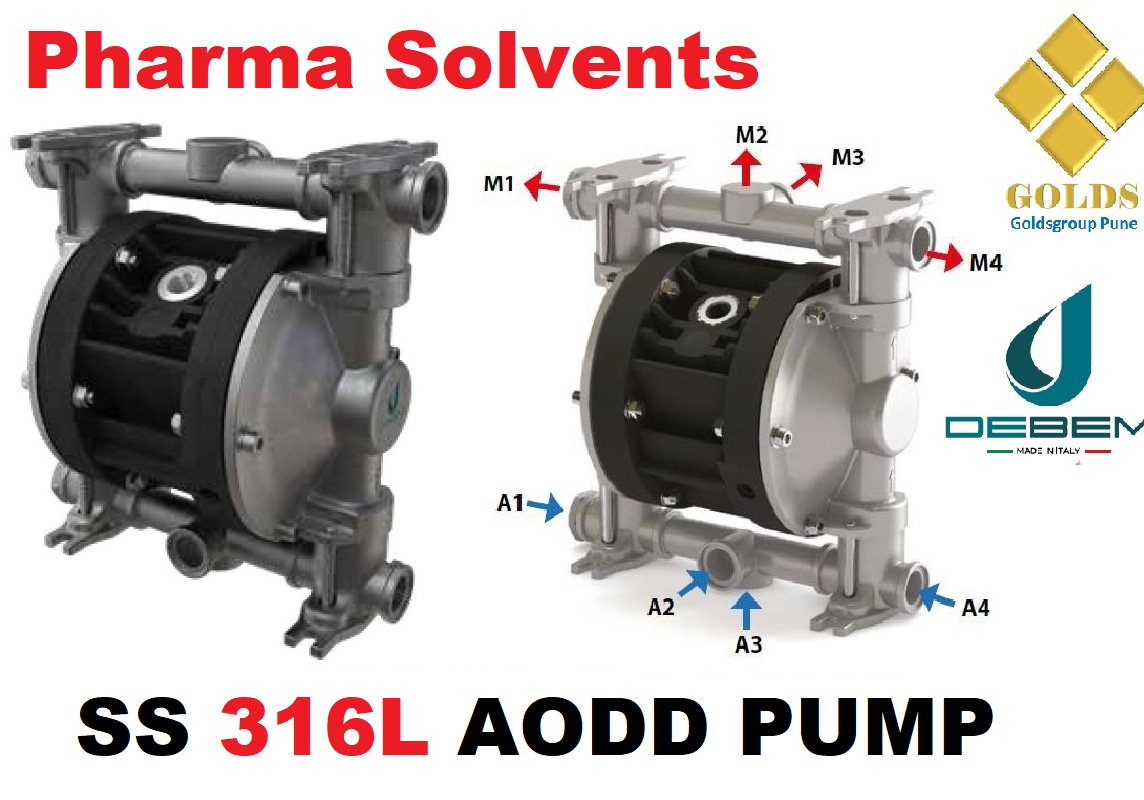

BOXER® - SS 316L Air Operated Double Diaphragm Pumps

We supply Pumps ONLY IN SS-316 L (Low Carbon Stainless Steel) v/s Std. SS-316 which are prone to Erosion-Corrosion and Metal Contamination

FOOD GRADE PUMP

More than 30% ENERGY SAVING

LESS IN VOLUME (Size)

PHARMA Solvents and Acids - IPA, MDC, EDC, Methanol, Ethanol, Butanol, Acetonitrile, Acetone, Toluene, Amines, Xylene, Hexane, Heptane, Mineral Turpentine Oil MTO, Butyl Acetate, Iso Butanol, Nitric Acid, Sulfuric Acid, Thionyl Chloride, MonoChloro Benzene etc....

CIP Fluids in PHARMA, FOOD, BEVERAGE, DAIRY Industry.

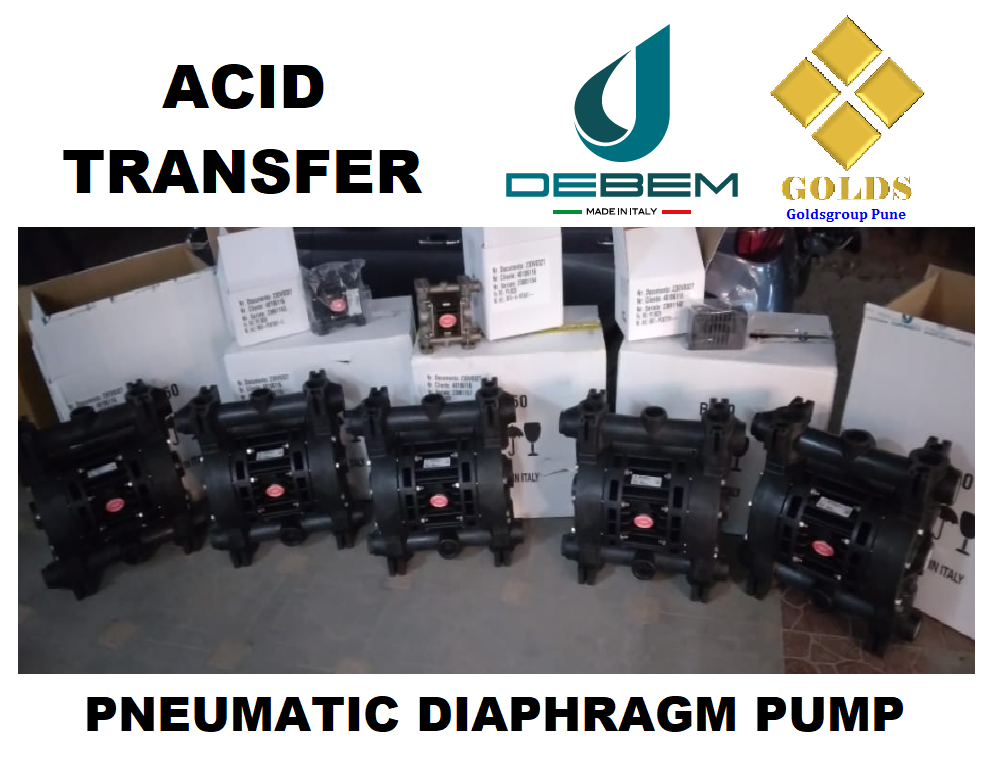

BOXER® - Pneumatic Acid Transfer Pump

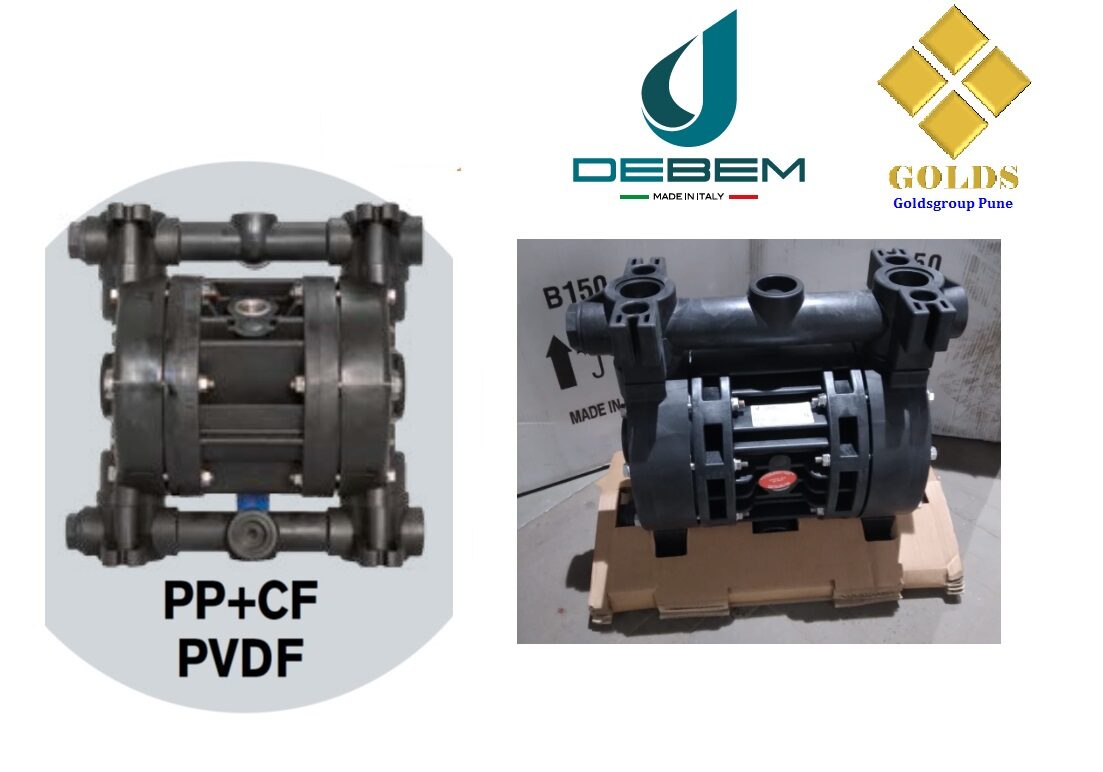

SMALLEST AODD PUMP - MICRO - MINI - LARGE - LARGEST - We have all types and sizes of Pneumatic Acid Transfer Pump, Acid Transfer Barrel Pump, Laboratory Testing Acid Pump and for various Industrial applications supplied in SPECIAL COMPOSITE MATERIALS such as PP + GLASS ADDITIVE, PP + CARBON FIBER, PVDF + CARBON FIBER to withstand and perform in challenging conditions. These are Flame Proof, Leak Proof, Seal Less Pumps.

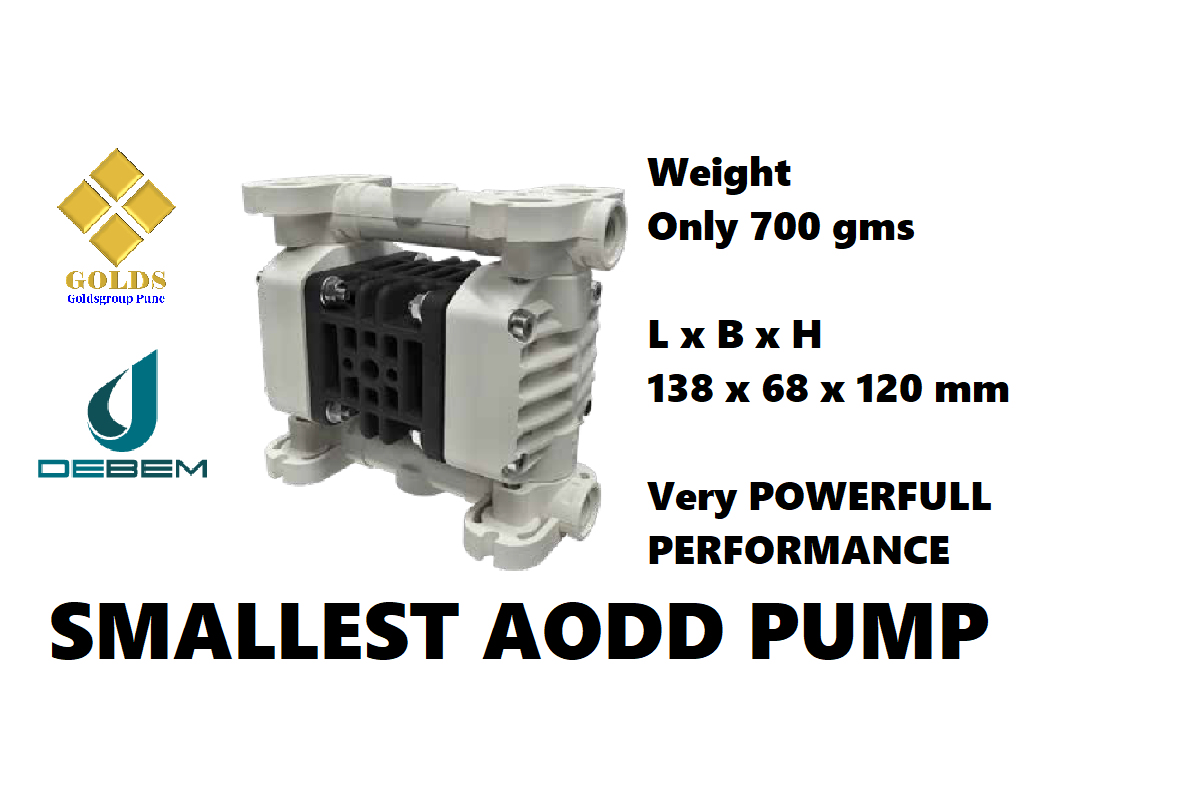

SMALLEST Air Operated Double Diaphragm Pump - AODD Pump

SMALLEST AODD PUMP delivers Powerful performance and has no match to it. Used as Pneumatic Acid Transfer Pneumatic Solvent Transfer Chemical Transfer Pump Pneumatic Barrel Pump Pneumatic Drum Pump for transfer of Small Quantity of Acids, Solvents, Chemicals to CAN BOTTLE filling and also used in Laboratory Testing

BOXER SMALL AODD PUMP SMALLEST AODD PUMP has become an synonym today in Industry

BOXER® - Pneumatic Diesel Transfer Pump - Pneumatic Pump for Diesel Transfer - Diesel Barrel Transfer Pump

Small in Size, Less in Weight, High Transfer Ratio, Easy to Use-Operate-Maintain BOXER Pneumatic Diesel Transfer Pumps are customers choice today.

ATEX Certified Explosion Proof Flame Proof Leak Proof Seal Less Pump is the SAFEST way to transfer DIESEL to DG SET or Barrels.

Widely used as Oil Barrel Transfer Pump, Lubricant Barrel Transfer Pump, Coolant Barrel Transfer Pump, Waste Oil Transfer Pump, Engine Oil, Gear Oil, Petrol Barrel Transfer Pump, Fuel Barrel Transfer Pump across Industry

AODD Pumps for FRUIT CONCENTRATES Transfer

Fruit and vegetable concentrate fluid handling operations require pumping operations that can preserve product integrity without compromising product quality. Fruit and vegetable pumps must provide gentle handling to avoid destruction of sensitive materials, such as fruits and vegetables, that could be damaged by pressure or shear forces. In addition, production efficiency and adherence to strict hygienic standards are essential to prevent contamination and ensure food safety, in compliance with key health and food regulations.

AODD pumps' answers to the pumping requirements of the fruit and vegetable sector

Double diaphragm pumps are the ideal solution for handling these types of requirements. Due to the special design configuration, these pumps can handle concentrate transfer processes with the following benefits.

- Gentle Pumping: double diaphragm pumps ensure gentle transfer of concentrates, avoiding mechanical damage to products and preserving their integrity.

- Precise Control: the ability to finely adjust pressure and flow allows pumping to be adapted to the specific needs of fruit and vegetable concentrates, optimizing the production process to the requirements of the fluid being handled.

- High hygienic standards: the AODD pumps are designed to meet the highest hygienic standards. Easy disassembly and compatibility with Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) processes ensure effective and rapid cleaning, reducing the risk of contamination.

- Efficiency and sustainability: efficiency in air consumption and reduced downtime contribute to a more sustainable production process, with less waste and reduced operating costs.

Debem's pumping solutions for transferring fruit and vegetable concentrates

Debem stands out in the market for its ability to offer food pumps that perfectly meet the requirements of the fruit and vegetable concentrate industry. The adoption of high-quality materials combined with innovative design ensures superior performance, long-term reliability and compliance with international food regulations. Specifically, the Aisiboxer and Saniboxer solutions, which are ideal for the needs of the industry, offer the following features.

- High-quality materials: The membranes are composed of food-grade PTFE supported by EPDM that can optimize flow and prevent product deposits.

- Patented pneumatic exchanger: A unique anti-stall system that provides superior performance with reduced air consumption.

- Hygienic design: The mechanically polished 316 L steel core body ensures an optimal surface finish to maintain high hygienic standards. Rotatable connections and special support for 360° rotation facilitate washing and sanitizing operations.

- Advanced Technology: Optical sensors to detect diaphragm damage and “eccentric” profile ball valves for solids passage.

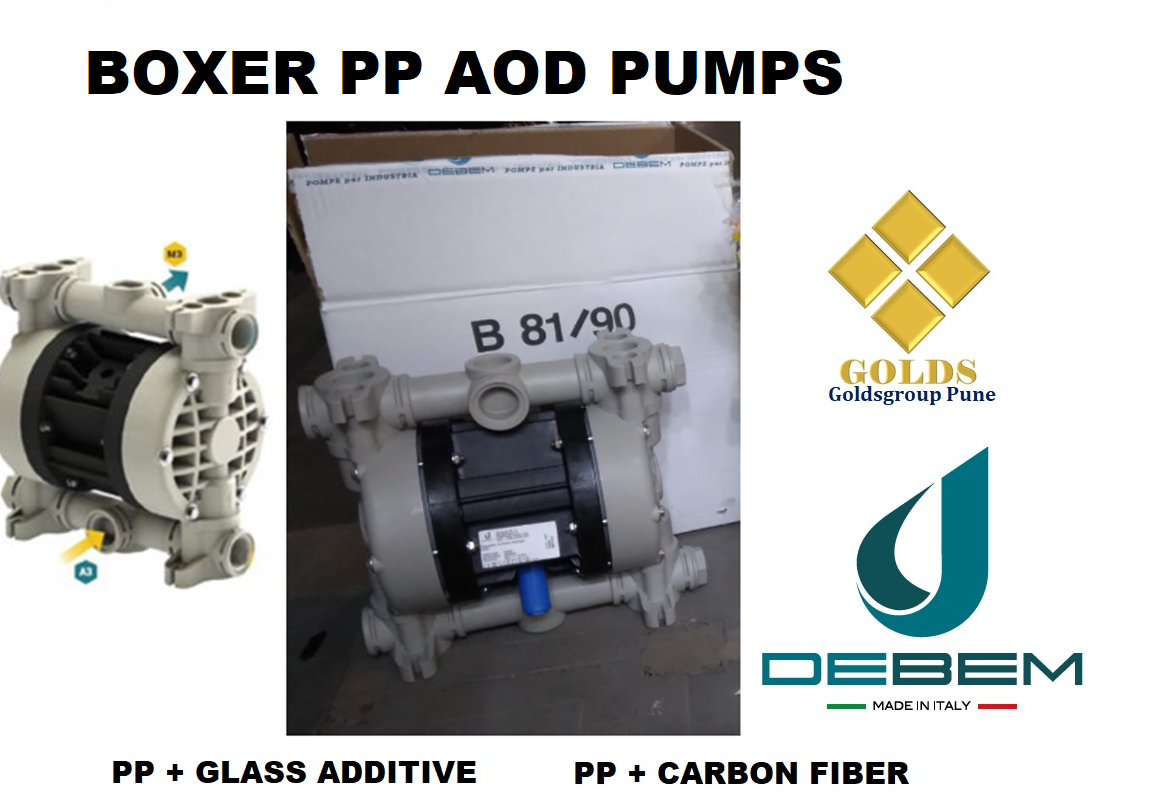

BOXER® - PP AODD Pump Plastic Pumps

Special COMPOSITE MATERIAL offered by us has proven Long Operational Service Life of PP AOD Pump offered by us.

Unique PP + GLASS ADDITIVE and PP + CARBON FIBER provide Highest Resistance to various Corrosive Acids used in various Industrial Applications.

More than 30% ENERGY SAVING

LESS IN VOLUME (Size)

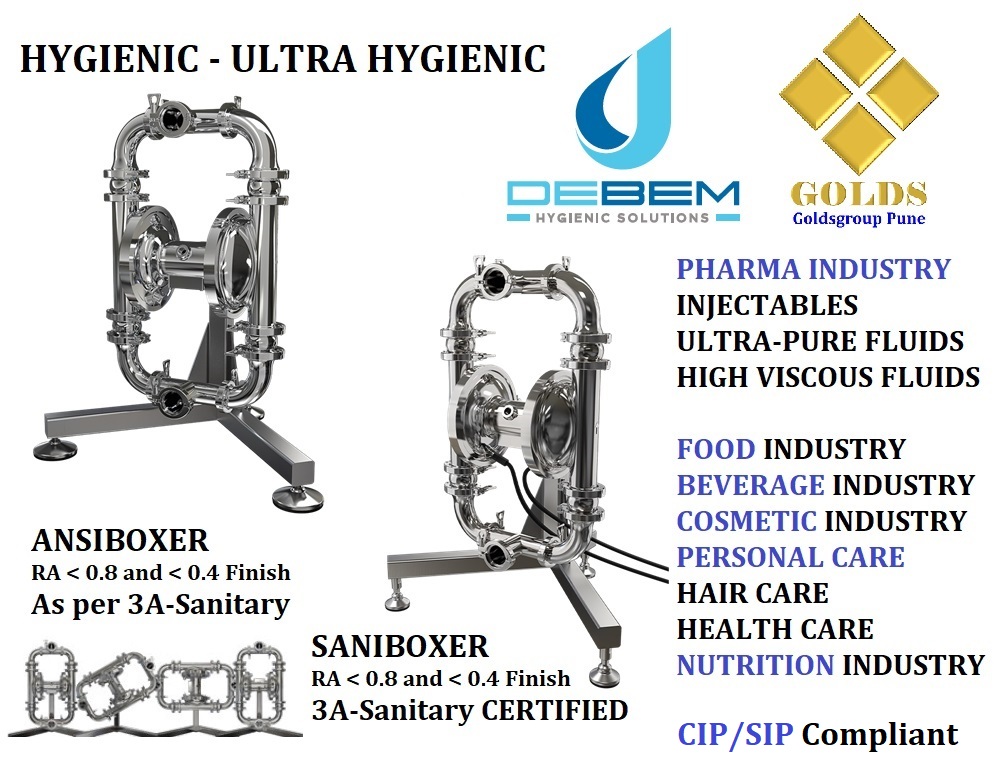

BOXER® - Hygienic Diaphragm Pump

Our HYGIENIC DIAPHRAGM PUMP Series offered in RA 0.8 and RA 0.4 Micron Finish ELECTRO POLISHED with FDA Grade Virgin PTFE and EPDM Internals are used for transfer of PURE and ULTRA PURE Liquids - in PHARMA, INJECTABLES, ULTRA PURE Liquids, HIGH VISCOUS Fluids, FOOD Industry, BEVERAGE Industry, COSMETIC Industry, PERSONAL CARE, HEALTH CARE, HAIR CARE, NUTRITION Industry these are CIP COP SIP Compliant as per FDA 3A SANITARY CERTIFIED and compliant as per USFDA norms.

FOOD GRADE PUMP

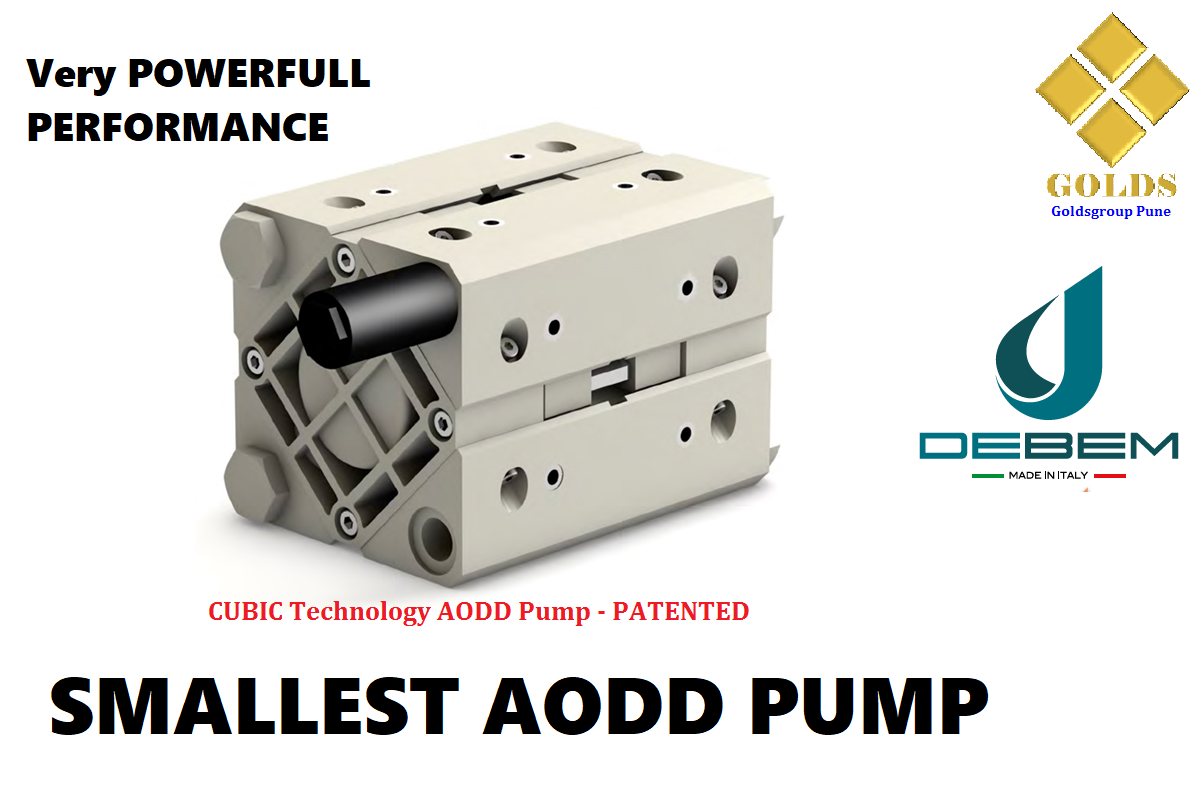

CUBIC® - SMALLEST AODD Pump

CUBIC AODD Pump CUBIC Diaphragm Pump Worldwide PATENTED SMALLEST AODD PUMP deliver powerful performance in Very LESS SPACE working with Acids, Solvents, Chemicals for Circulation and Transfer application especially on Machine where Space is a Major Constraint.

ECTFE, PP + GLASS ADDITIVE, PP + CARBON FIBER Materials makes it almost Universal use pump in all Industrial applications

BOXER® - POLYOL ISOCYANATE CYCLOPENTANE Transfer AODD Pump Series

PU Industry highly relies on our BOXER AODD Pumps for transfer of Polyol Isocyanate Cyclopentane which work on both AIR as well as NITROGEN supply. Methylene di Isocyanate MDI transfer usage is also very popular. They deliver in both Reactor Pressurized and Rector De-Pressurized conditions.

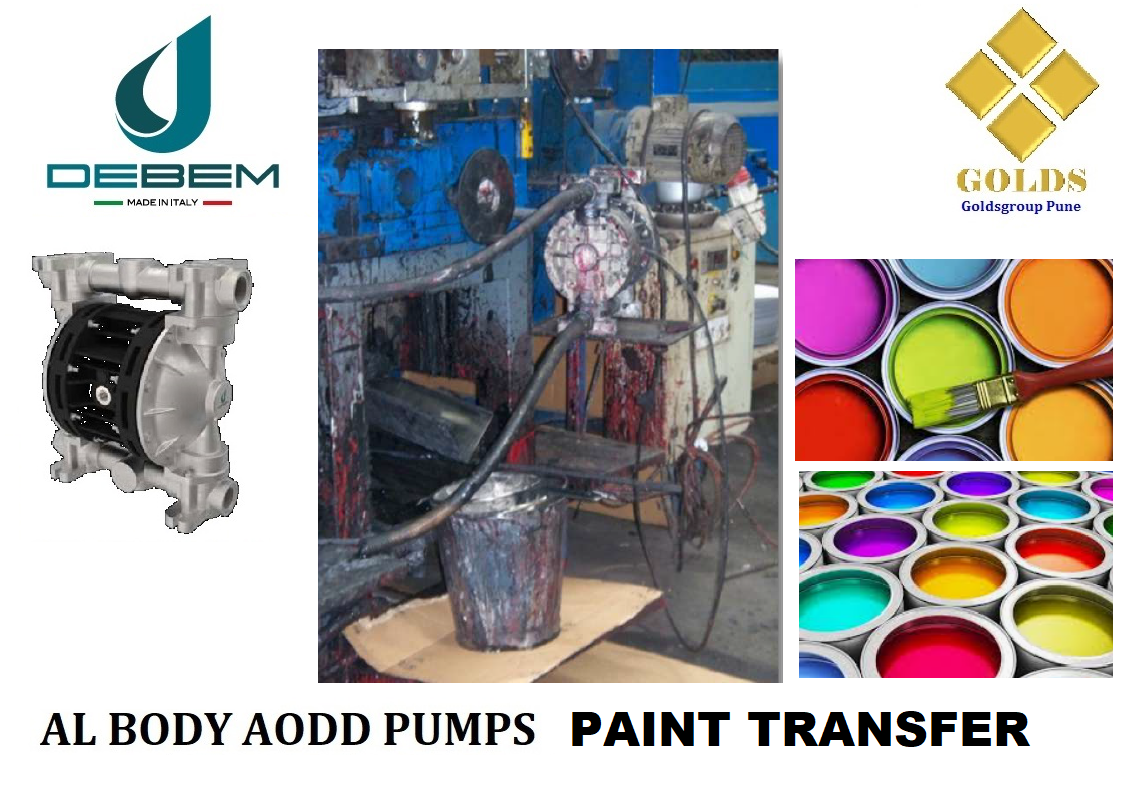

BOXER PAINT Transfer AODD Pump 1" Size

BOXER Pneumatic Diaphragm Pumps are widely used for Transfer of Paints, Transfer of Emulsions, Transfer of Dispersions, Transfer of Hardeners, Solvents, Slurry and many other fluids in PAINT and COATING Manufacturing Industry.

The advantages of AODD technology in milking pumps

Production facilities in the dairy sector require automated processes aimed at enabling safe transport of the product by minimizing the risks of leaks or residues remaining inside the plant.

Double diaphragm pumps for dairy industry

AODD pumps are suitable for use in numerous applications in the dairy industry, including the transfer, mixing and dosing of ingredients and raw materials, drum filling and emptying, and plant recirculation operations. Dairy double diaphragm pumps are also capable of handling viscous liquids and fluids containing suspended solids. This versatility makes them particularly suitable for pumping different types of liquids including cottage cheese cream, cream, ice cream mixtures, syrups and toppings, yogurt, margarine, butter and other fats.

The advantages of AODD technology in milking pumps

The advantages of using double membrane pumps in the dairy industry can be summarized in the following points.

- Design configuration: the configuration of an appropriately spaced through-flow within the pump promotes the transfer of viscous liquids or fluids with solids without the risk of generating clogging in the pump and consequently operational blockages in the system.

- Shear sensitivity: AODD pumps promote a gentle pumping action that avoids damage to shear-sensitive products. When transferring highly viscous liquids, the pumping speed is automatically reduced to a stop (when liquid conditions no longer allow for transfer) while avoiding the risks of pump damage.

- Self-priming capability: the double diaphragm pump is capable of drawing liquid when placed above the level of the fluid to be pumped. This advantage makes the pump usable in several placement scenarios.

- Ability to work dry: if during the pumping action the liquid runs out, the pump retains the ability to work dry without generating any damage to its internal parts.

- No electricity: AODD pumps are powered entirely by compressed air and can therefore be used in applications where electricity is not available or cannot be used.

- Low maintenance costs: double-diaphragm pumps generally consist of a small number of elements. The membranes are easily disassembled and replaced. These factors help to keep maintenance costs low.

Adaptation of Debem milk dairy pumps to hygienic and sanitary regulatory requirements

The hygienic pumps for milk products manufactured by Debem, in addition to the advantages listed in the preceding paragraphs, have an important application benefit arising mainly from the materials used in their manufacture.

Specifically, the Debem hygienic pump body is composed of a single block of mechanically polished 316 L steel with Ra < 0.8 µm surface finish. The diaphragms, on the other hand, are lined with a food-grade PTFE part in contact with the fluid, supported by a layer of EPDM. These materials enable the pump to operate efficiently and reliably while reducing the risk of damage (e.g., when in contact with abrasive liquids) or contamination of the product (e.g., when liquid meets pump parts). The resistance of these materials to aggressive chemicals also enables the pump to support CIP (cleaning in place) processes without the risk of wear or damage. The use of these materials also enables Debem hygienic pumps to comply with the industry’s most important certifications such as the FDA (Food & Drug Administration), 3A (Sanitary Standards Administrative Council) and MOCA.

BOXER® - Non Metallic Pump - PVDF AODD Pump

Special COMPOSITE MATERIAL offered by us PVDF + CARBON FIBER has proven Long Operational Service Life especially with Highly CORROSIVE Acids, Liquids having Temperature and Solid Content giving ABRASION RESISTANCE and Lowering THERMAL EXPANSION of our PVDF AOD PUMPS.

More than 30% ENERGY SAVING

LESS IN WEIGHT-VOLUME (Size)

FDA BOXER® - FDA Air Operated Double Diaphragm Pump - FDA Pneumatic Diaphragm Pump Series

FDA BOXER Series are offered in RA 2.7 Micron Finish ELECTRO POLISHED with FDA Grade Virgin PTFE Internals for applications which DO NOT required RA 0.8 or RA 0.4 Micron Finish ELECTRO POLISHED Pumps but need HYGIENIC Conditions USFDA ATEX ZONE 1 Compliance for transfer of Solvents, Alcohols, Perfumes etc.... in Clamp or Tri-Clamp Connection

FOOD GRADE PUMP

HYGIENIC DIAPHRAGM PUMP

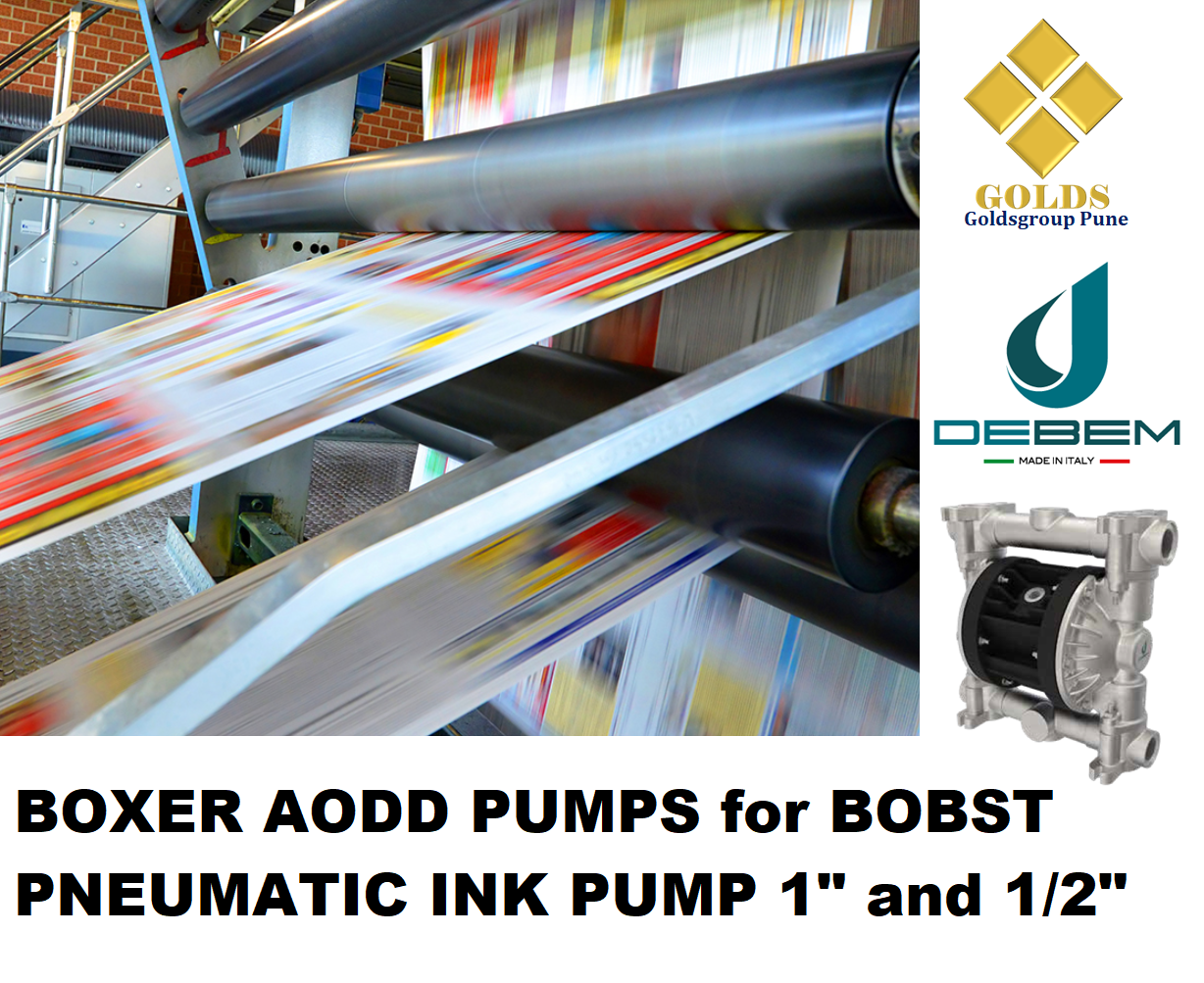

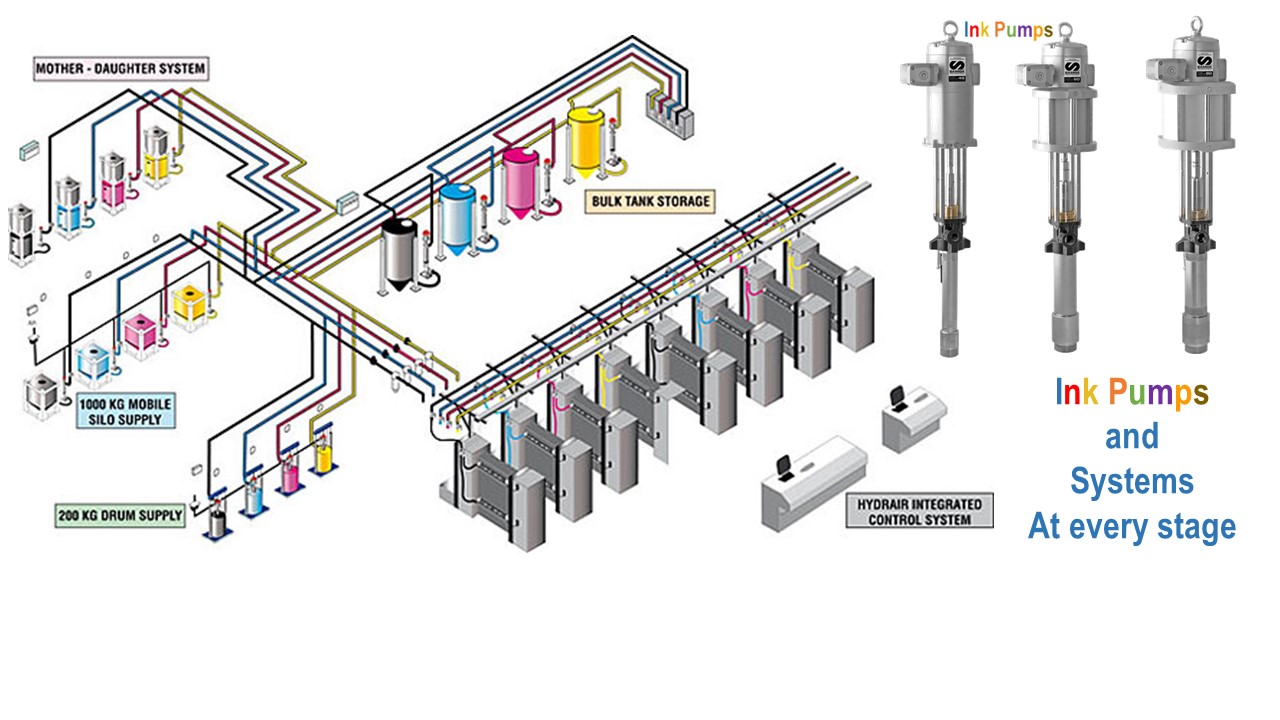

BOXER® - Pneumatic Ink Pump - Ink Circulation Pump

Widely used on BOBST Machines RS 5002 RS 5003 RS 6002 RS 6003 etc.... Pneumatic Ink Pump Pneumatic Ink Circulation Pump used Inks Solvents application in Printing and Packaging Plant

1" Size and 1/2" Size are widely used in AL Body delivered with Unique SS 316 Balls and SS 316 Ball Seats that provide High Transfer Ratio and Less Stress to Pump effectively offering Superior Operational Service Life with minimal parts replacement

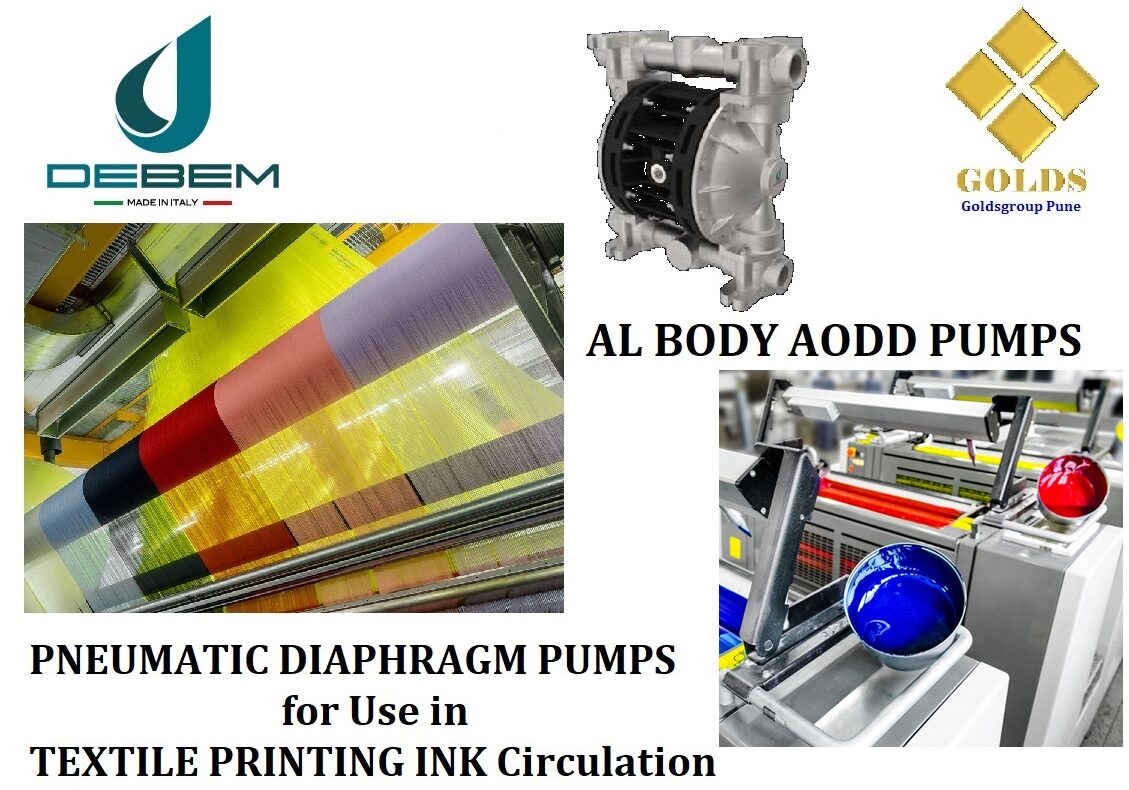

BOXER® - AODD Pumps for the Textile and Leather Industry

Pumps for the textile and leather industry

Debem pumps are ideally suited for supplying roller coaters, transferring printing inks for textiles, for dyeing and finishing systems, for supplying roller coaters for plastic coating, for centralised lubrication systems, colorant distribution system, supplying leather painting systems, pumping acid solutions, supplying roller coaters for imitation leather or in colorant distribution systems (batches formulation plant), dyes transfer in textile printing plants and tanneries.

How can AODD pumps improve carbonated beverage production processes?

The non-alcoholic beverage market is characterized by the presence of plants, operated by multinational or third-party companies, used for preservation and bottling through a production flow that involves the processing of particular ingredients, including corn syrup, fructose, various concentrating substances, flavorings and phosphoric acid. The result of the production process is the soft drink that is marketed in stores and made available to end consumers.

What these soft drink production operations have in common is strict adherence to strict production protocols so that the finished product lives up to the brand’s taste and regulatory-hygienic standards of the industry.

The production process of soft drinks

A pattern that unites the production processes of soft drinks can be described in the following points:

- The common water, used in the composition of the beverage, is treated to remove any impurities that may alter the taste or color.

- The next step involves sterilizing the treated water to destroy any residual bacteria or organic compounds.

- The sterilized water “rests” in a storage tank and flows through an activated carbon filter that performs a dichlorination operation.

- This is followed by the addition of a premixed concentrate substance that is pumped to a dosing station, where it is combined with the water

- This concentrate/water mixture moves to a “batch” tank where it is mixed to form the base of the soft drink and then pasteurized instantaneously.

- The mixture passes through a carbonator that adds carbonation at predetermined levels according to the soft drink recipe

- The finished product is transferred to the filling lines where it is injected into bottles and cans later packaged in cartons or trays for shipment to distributors.

Advantages of AODD pumps in beverage production

The line of AODD food pumps designed by DEBEM offer several operational advantages that make them more suitable for soft drink production than centrifugal pumps. The main operational advantages of AODD pumps in beverage production are as follows:

- Simplified design: The simplicity of AODD pumps makes them very attractive to the beverage industry. “Plug in and play” functional features combined with a highly effective ability to pump most substances makes them the pump of choice for many in the industry.

- Ability to run dry and self-priming: the double diaphragm pump will not be damaged when operating without fluid. In addition, they are able to suck in fluids even when the pump is not potted.

- Chemical resistance: double diaphragm pumps do not involve direct contact of the components with the liquid to be conveyed. Thus, the diaphragm pump can smoothly handle liquids that are not perfectly filtered or have residual solid particles or acids, solvents and abrasive particles.

- Safety: Because AODD pumps use compressed air as their sole power source, they are intrinsically safe and are available ATEX certified for use in applications where electricity cannot be used.

The Aisiboxer and Saniboxer food pumps offer the ability to pump a wide range of viscosities and shear-sensitive products and are perfect for handling corn syrups, phosphoric acids, concentrates and flavorings, all of which are critical in soft drink production. Their high versatility of operation and design features make them the right solution for the industry. In particular, the mechanically polished ASISI 316 L material is particularly important for handling food substances according to strict industry regulations.

The use of centrifugal pumps within the beverage industry

Centrifugal pumps have been a staple within the beverage production industry for many years. However, although characterized by lower purchase costs, they can have operational inefficiencies with subsequent higher lifetime costs. For example, centrifugal pumps are not self-priming, may falter when pumping high-viscosity liquids, are unable to run dry, have mechanical seals that are prone to leakage, and are driven by electric motors that must be kept dry during operation.

Conclusion

DEBEM’s line of food pumps is an optimal choice for the many points of liquid processing and handling within a soft drink packaging plant. The use of DEBEM’s AODD pumps can help achieve high product quality standards while reducing operating and maintenance costs. Contact our sales team for more information.

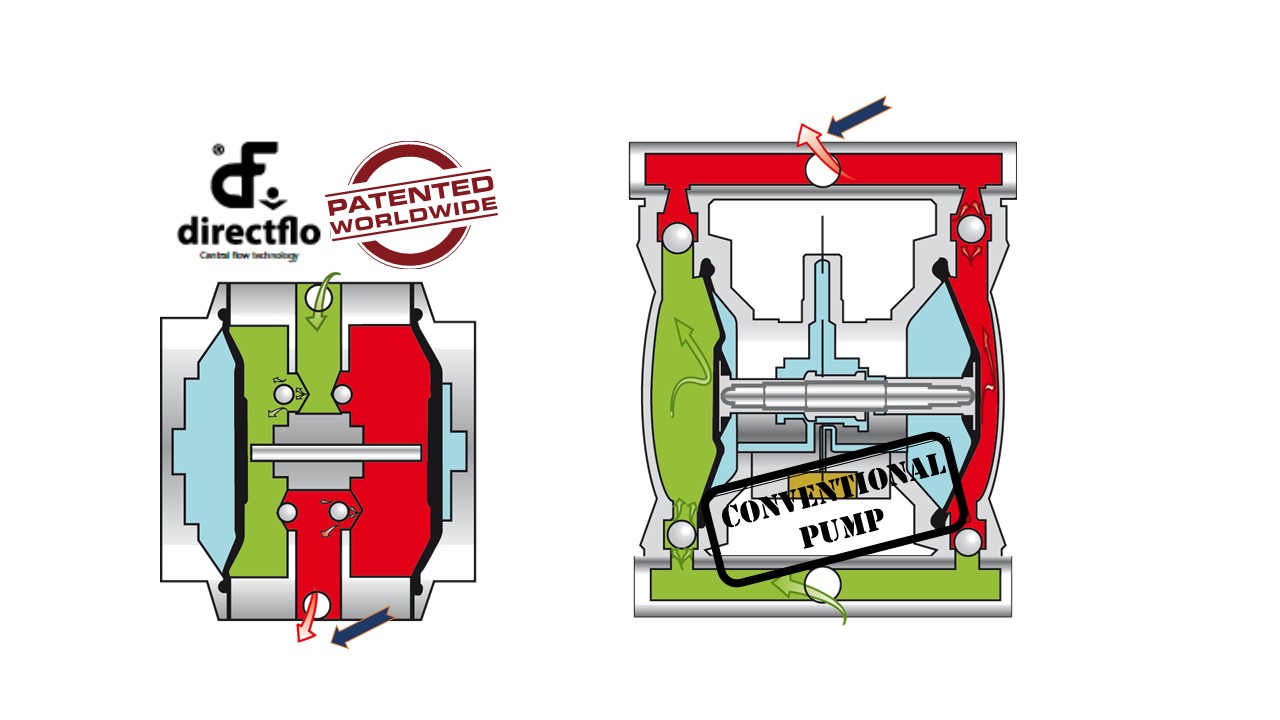

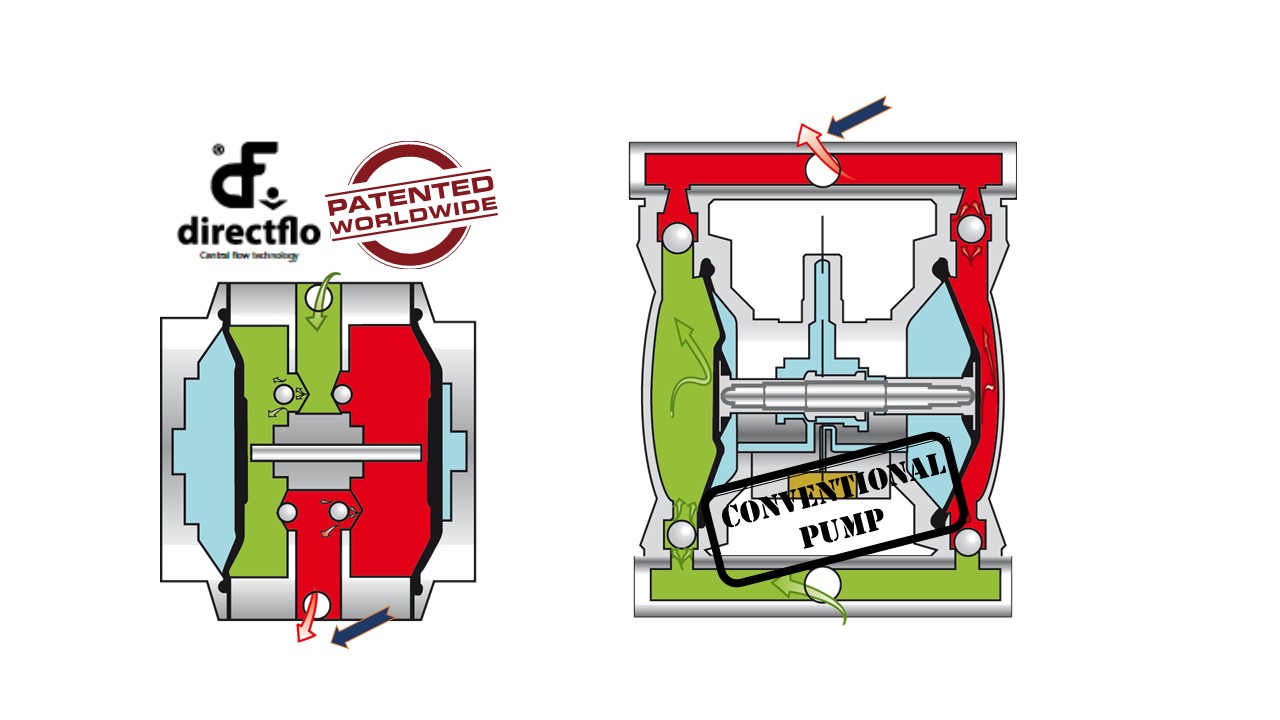

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

Evolved over 10 years of rigorous in-house R & D : Year 2000 - 2010

More than 40% ENERGY SAVING

More than 50% LESS IN VOLUME (Size)

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

Central flow design – reduces internal hydraulic losses, together with an efficient air valve with reduced air losses, delivers reduced air consumption per liter pumped.

Central flow provides full serviceability of the pump without removing it from the fluid inlet and outlet lines.

NO MANIFOLD DESIGN = Minimal Pressure Drop Inside

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

FDS Concept : Flexible Diaphragm Suspension incorporated - instead of fixing the diaphragms rigidly to the shaft, all Directflo® diaphragm adapters slide on the pump shaft.

FPV - Frictionless Pivoting Air Valve - Non-stalling, non-icing, self-cleaning, tolerates non-lubricated, dirty, damp or oily air. It has high operational reliability. No Air Leaks when pump stops hence air consumption reduced up to or more than 40%.

Design ensures – Longer diaphragm life, Reduced number of parts count, Longer mean time between maintenance, Fast, non expert, repair or in-line servicing ~ 2.4 Times Reduction in Maintenance Time and thereby COST.

Short strokes to minimize diaphragm deformation and hence reduces material strain.

Reduced pulsation and noise.

Reliable start-up with LOW AIR PRESSURE

Innovative Bonded PTFE Diaphragms

Single Part Molded Pump Body

Flange Fastening Plates - for plastic pumps

Significant DRY SUCTION LIFE capability eliminates self-priming issues

Discharge fluids at up to 7 bar (100 psi) for even medium viscosity fluids over long pipe runs and up to significant heights

ATEX Certified Pumps available for explosion proof applications.

Directflo® - DUAL INLET - AODD Pump Series

- DF30T & DF50T Dual Inlet pumps for 1:1 ratio mixing of fluids with similar viscosity.

- Flow and pressure variants available

Directflo® - CUSTOM SERIES - 1/4" AODD Pump Series

- 1/4" AODD pump developed especially for higher Efficiency, higher Reliability and Smoother-Less Pulsating Flows for DOSING and SMALL FLOW applications

- Includes all DIRECTFLO features and advantages

- Oriental INLET and OUTLET - flexibility for OEM's

- Easy to remove AIR-LOCKS mechanism developed and incorporated

- New Spool Valve developed and incorporated

- New Pneumatic Sensors for Sleeve Valves

- Longer life of cages

Directflo® - PERFORMER SERIES- 1" AODD Pump

- 1" PERFORMER SERIES AODD pump developed especially for higher FLOW - 200 l/min (53 gal/min)

- Available in PLASTIC as well as METAL configuration

- Maximum Flow with Minimum Air Consumption for an 1" pump

- Oriental Ports - increased installation Flexibility

- Oriental INLET and OUTLET - flexibility for OEM's

- higher Reliability and Smoother-Less Pulsating Flows

- Includes all DIRECTFLO features and advantages

- Pump is much Narrow

- Easy to remove AIR-LOCKS mechanism developed and incorporated

- Longer Life when used with Abrasive Materials

- Possibility of Not Using Seals - available for specific applications

- ONLY One Spanner required for entire pump maintenance

- Outlet Manifold with Top Cap can be positioned in the Lateral Outlet for requirement of TOP OUTLET

- Side covers easily adaptable to mount different types of sensors

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

Evolved over 10 years of rigorous in-house R & D : Year 2000 - 2010

More than 40% ENERGY SAVING

More than 50% LESS IN VOLUME (Size)

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

Central flow design – reduces internal hydraulic losses, together with an efficient air valve with reduced air losses, delivers reduced air consumption per liter pumped.

Central flow provides full serviceability of the pump without removing it from the fluid inlet and outlet lines.

NO MANIFOLD DESIGN = Minimal Pressure Drop Inside

Directflo® - Air Operated Double Diaphragm Pump - AODD Pump

FDS Concept : Flexible Diaphragm Suspension incorporated - instead of fixing the diaphragms rigidly to the shaft, all Directflo® diaphragm adapters slide on the pump shaft.

FPV - Frictionless Pivoting Air Valve - Non-stalling, non-icing, self-cleaning, tolerates non-lubricated, dirty, damp or oily air. It has high operational reliability. No Air Leaks when pump stops hence air consumption reduced up to or more than 40%.

Design ensures – Longer diaphragm life, Reduced number of parts count, Longer mean time between maintenance, Fast, non expert, repair or in-line servicing ~ 2.4 Times Reduction in Maintenance Time and thereby COST.

Short strokes to minimize diaphragm deformation and hence reduces material strain.

Reduced pulsation and noise.

Reliable start-up with LOW AIR PRESSURE

Innovative Bonded PTFE Diaphragms

Single Part Molded Pump Body

Flange Fastening Plates - for plastic pumps

Significant DRY SUCTION LIFE capability eliminates self-priming issues

Discharge fluids at up to 7 bar (100 psi) for even medium viscosity fluids over long pipe runs and up to significant heights

ATEX Certified Pumps available for explosion proof applications.

Directflo® - DUAL INLET - AODD Pump Series

- DF30T & DF50T Dual Inlet pumps for 1:1 ratio mixing of fluids with similar viscosity.

- Flow and pressure variants available

Directflo® - CUSTOM SERIES - 1/4" AODD Pump Series

- 1/4" AODD pump developed especially for higher Efficiency, higher Reliability and Smoother-Less Pulsating Flows for DOSING and SMALL FLOW applications

- Includes all DIRECTFLO features and advantages

- Oriental INLET and OUTLET - flexibility for OEM's

- Easy to remove AIR-LOCKS mechanism developed and incorporated

- New Spool Valve developed and incorporated

- New Pneumatic Sensors for Sleeve Valves

- Longer life of cages

Directflo® - PERFORMER SERIES- 1" AODD Pump

- 1" PERFORMER SERIES AODD pump developed especially for higher FLOW - 200 l/min (53 gal/min)

- Available in PLASTIC as well as METAL configuration

- Maximum Flow with Minimum Air Consumption for an 1" pump

- Oriental Ports - increased installation Flexibility

- Oriental INLET and OUTLET - flexibility for OEM's

- higher Reliability and Smoother-Less Pulsating Flows

- Includes all DIRECTFLO features and advantages

- Pump is much Narrow

- Easy to remove AIR-LOCKS mechanism developed and incorporated

- Longer Life when used with Abrasive Materials

- Possibility of Not Using Seals - available for specific applications

- ONLY One Spanner required for entire pump maintenance

- Outlet Manifold with Top Cap can be positioned in the Lateral Outlet for requirement of TOP OUTLET

- Side covers easily adaptable to mount different types of sensors

INK PUMP SERIES

Mainly for Applications in -

INK Manufacturing

INK Distribution Systems

INK Control Systems

INK Storage Systems

Packaging Industry

New Paper Printing

Packaging Industry

Next Steps...

Have an Application in mind?

Want to request a quote? or

Want to peruse our product catalog....